MABATI PRODUCTS

The Mabati Division seeks to provide quality products that fit a diverse niche in the construction industry. Using the latest technological innovations, Corrugated Sheets Limited produces Nyumba mabati that range from galvanized iron sheets, Aluminium Zinc Alloy coated sheets and pre-painted sheets. Uses for mabati products may differ according to client needs and market demands, but by producing diverse Mabati products, we hope to anticipate diverse client needs.

The Mabati Division includes:

Pre-painted steel is the one of the greatest revolution in the coating Industry. The technology is not more than two decades old, but its diversified uses have been universally applied in different industries. Generally, pre-painted steel is used for roofing, walling, fencing, sandwich panels and in situations where the metal-coated steel is not sustained longer. Nyumba Colourcoat Mabati is produced by the latest continuous colour-coating technology and machinery.

Nyumba Colourcoat Mabati is protected by triple layers:

- The metal coating provides sacrificial protection and acts as a tough physical barrier between the extreme atmospheric conditions and the inner core of steel

- A Chromium-6 (Hexavalent chromium) base pre-treatment provides a good barrier that prevents the oxidation of the coated metal.

- Paint is a polymer-based compound with other solvents and has good resistance to water, moisture, and dust. Hence it extends the steel life in years.

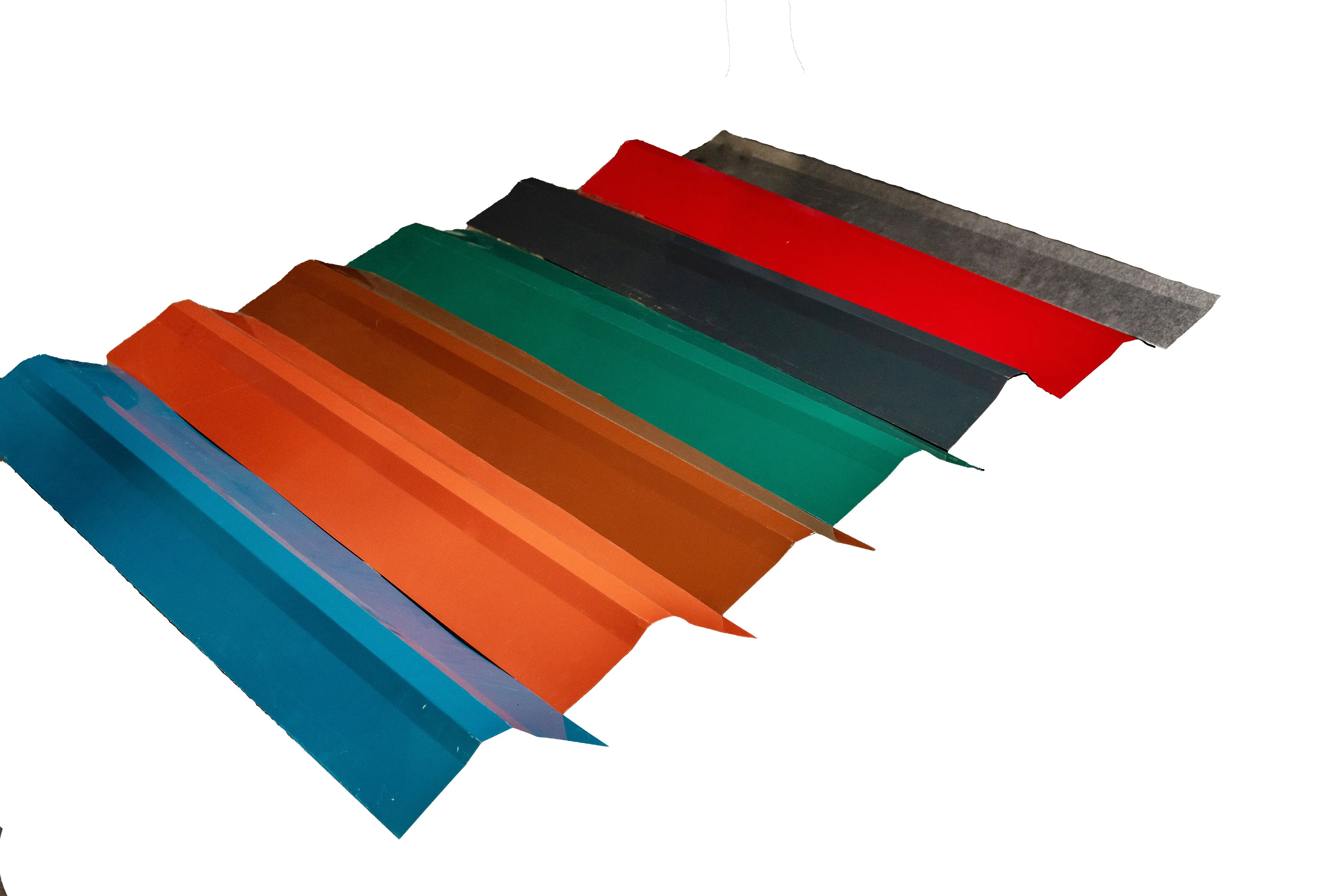

Available Colours (Top Color)

Pantone Green

Charcoal Grey

Sky Blue

Brick Red

Valentine Red

Tile Red

Cream

Dark Green

Any other Colour - Available on Special Order

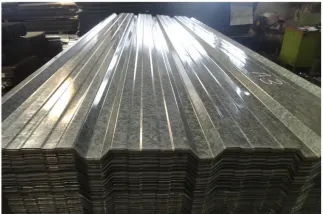

NYUMBA 11/3 CORRUGATION PROFILES COLOURCOT

- Number of Corrugations 11

- Effective/Covering Width 752 ± (5 mm)

- Overall Width 850 ± (5 mm)

- Standard Length - 2.0 / 2.5 / 3.0

- Metres Special Length - Any Length on Special Order

- Thickness Available 30 / 28 / 26 / 24 Gauge

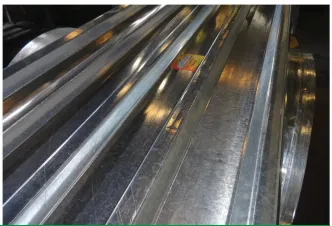

NYUMBA IT-4 AND IT-5 INDUSTRIAL PROFILES

- Number of Troughs - Four or Five

- Effective Width - 686mm, 855mm (± 5mm)

- Overall Width 755 / 906 mm (± 5mm)

- Lengths Any Length Over 2.0 Metres

- Thickness Available 30 / 28 / 26 / 24 Gauge

NYUMBA MAX PROFILE COLOURCOT

- Number of Troughs - Four or Five

- Effective Width - 780mm, 980mm (± 5mm)

- Overall Width 860 / 1020 mm (± 5mm)

- Lengths Any Length Over 2.0 Metres

- Thickness Available 30 / 28 / 26 / 24 Gauge

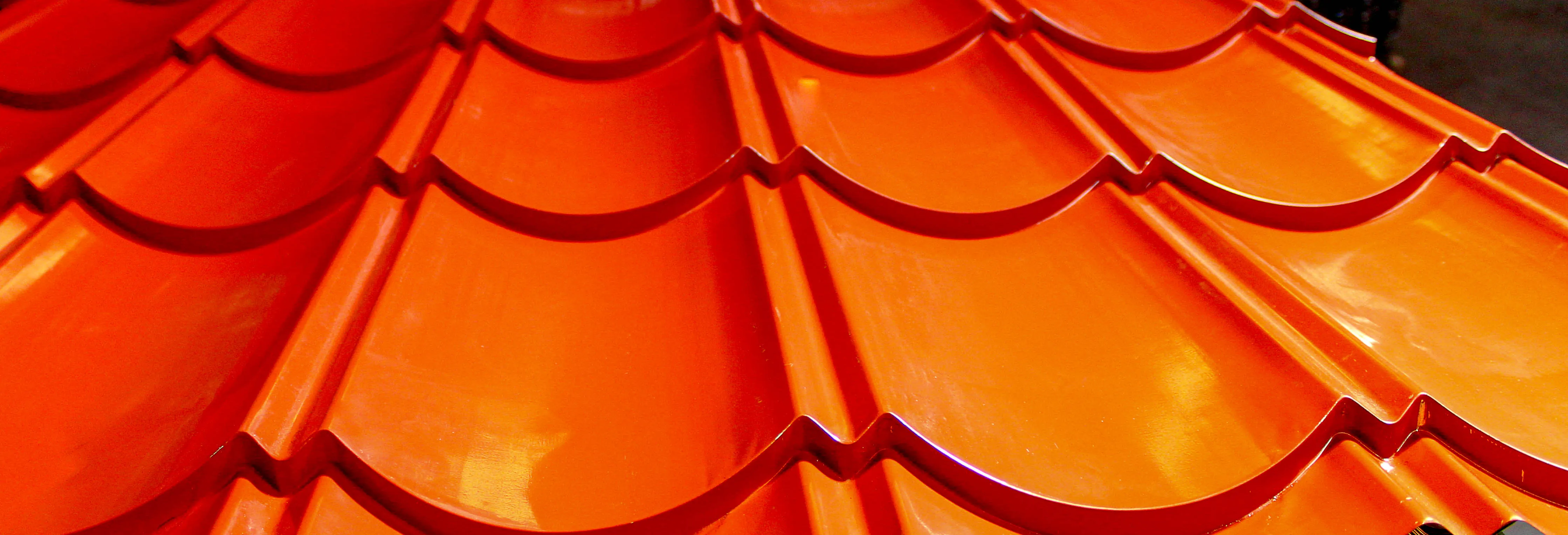

NYUMBA CLASSICAL TILE PROFILE

- Effective / Covering Width - 1015mm (± 5mm)

- Overall Width - 1077mm (± 5mm)

- Standard Lengths 2.1, 2.4, 2.7, 3.0 Metres

- Special Lengths - Any Length on Special Order

- Thickness 24, 26, 28 Gauge

NYUMBA BRICKTILE PROFILE

- Effective / Covering Width - 1060mm (± 5mm)

- Overall Width - 1130mm (± 5mm)

- Standard Lengths - 2.1, 2.4, 2.7 & 3 Meters

- Special Lengths - Any Length on Special Order

- Thickness - 28 & 26 Gauge

NYUMBA WAVETILE PROFILE

- Effective Width 1000 ± 5mm

- Overall Width - 1120 ± 5mm

- Standard Lengths 2.1, 2.4, 2.7 & 3 Meters

- Special Lengths Any Length on Special Order

- Thickness 26 and 28 Gauges

NYUMBA PRE-PAINTED / COLOURCOT COILS

- Minimum individual coil weight available : 4 - 8 tonnes individual coil weight

- Custom colour available on order.

- Custom colour minimum order 20 tonnes (Not individual coil weight)

NYUMBA PLAIN SHEET COLOURCOT

- Size 2m by 1m

- Custom length available max 3m

- Custom colour available on order : Minimum order 5 tonnes

Roofing Accessories

NYUMBA COLORCOT RIDGES (PREPAINTED)

- Width 325mm

- Length 2000mm

- Thickness 30 / 28 / 26 / 24 Gauge

TILE RIDGES

- Pitch 190 (± 15mm)

- Overall Dimension 316 mm (± 20mm)

- Standard Length 2m

- Special Lengths Any Length on Special Order

- Thickness 26 and 28 Gauges

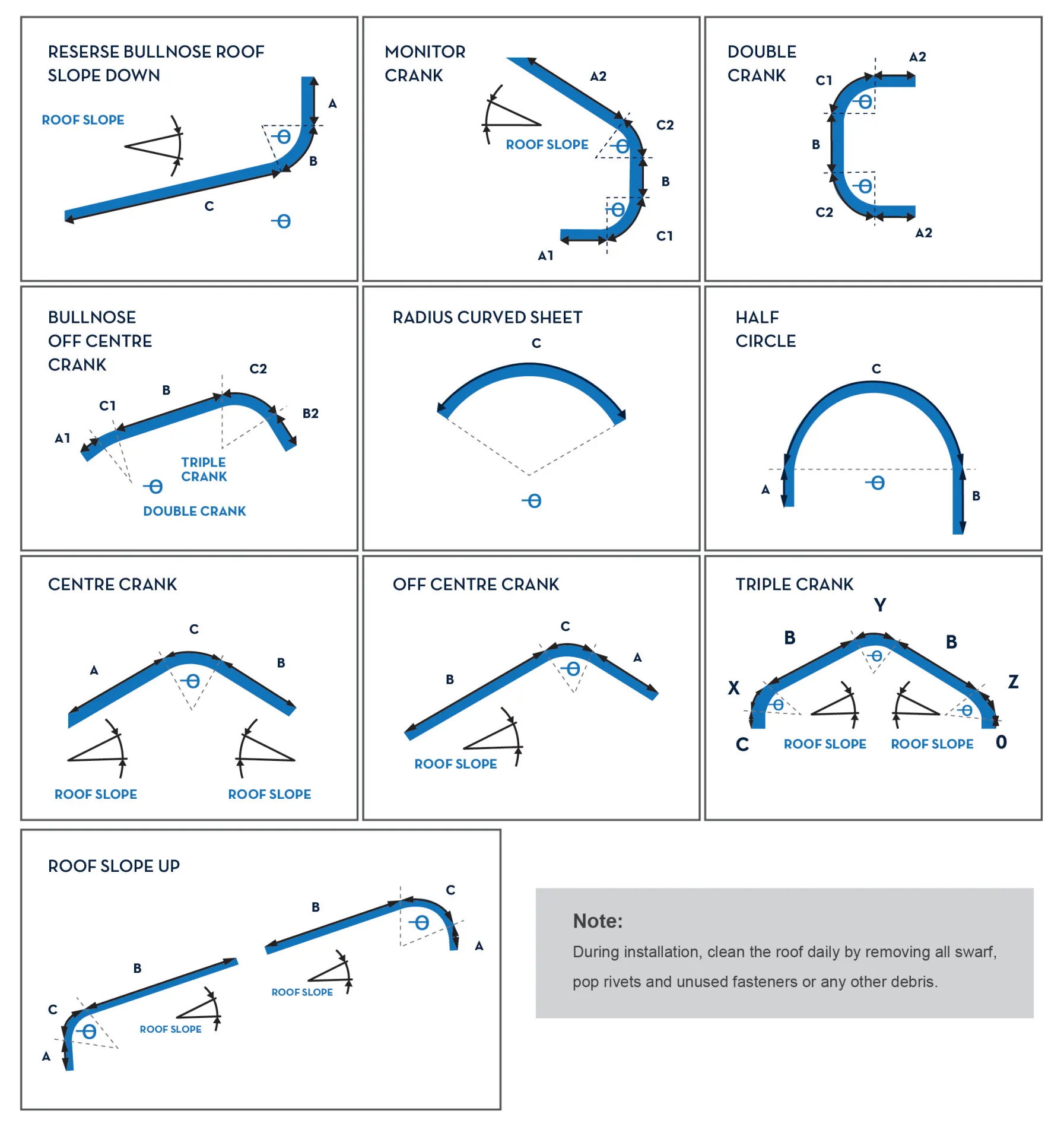

NYUMBA CURVED / CRIMPED SHEETS

- Length 2000mm

- Width 300mm

- Thickness 28 / 26 / 24 Gauge

These drawings show the various types of bullnosing and cranking available on Nyumba group. Before production may commence, we will require a detailed drawing giving all the required data, and duly authorized by the customer.

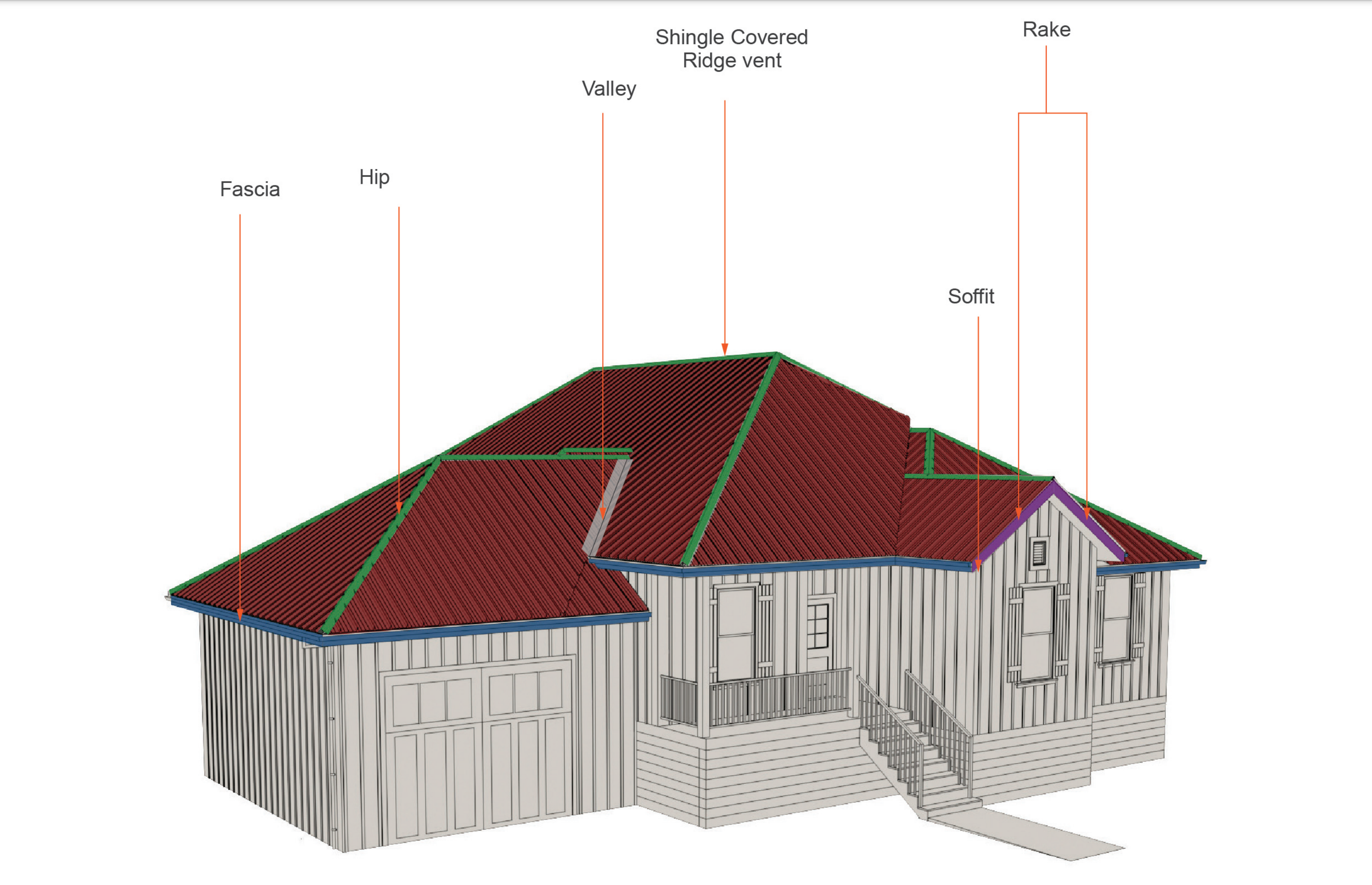

ROOFING TERMINOLOGY

- Care has been taken to ensure that the information provided is accurate. Corrugated Sheets Limited does not assume responsibility for inaccuracies or misinterpretations of this data.

- Corrugated Sheets Limited is continuously engaged in product development, please ensure that you have the most recent issue of information from Corrugated Sheets Limited.

- Photographs and illustrations are typical examples of roofing and cladding products and cladding products and applications.

Proper usage and handling of mabati products

Storage

Wet storage stain

Steel sheets are normally treated with a special chromate solution, under strictly controlled conditions (i.e. the sheet is passivated) before leaving the Mill. Although this process ensures long and satisfactory protection to sheets, wet storage stain or white rust can still occur. One of the main conditions which may give rise to this problem is sheets being exposed to water while stacked, which restricts air circulation between sheets. It is therefore important that sheets remain dry and that they do not come into contact with each other at any point if exposed to water. If sheets cannot be stored in a dry storage space, they should be stood on end and spaced out at the bottom. A drop in temperature after a warm, humid day may also lead to condensation of moisture throughout the stack. And because the temperature is usually at its lowest during the night, the risk of condensation is increased. The stain that is created does not compromise the integrity of the sheet, but does have a negative impact on the aesthetic value.

Technical

Edge wave and oil canning

The amount of edge wave or oil canning is dependant upon the varying mechanical properties of the coil used. Stiffeners ribs are incorporated into the troughs to minimise the effects of oil canning.

Surface contamination

Care should be taken to ensure that none of the debris arising from the fixing of steel roof remains on the sheets after completion of work. If nails, swarf, etc. are allowed to remain on roof sheets, unsightly spots will soon appear. Initially these rust sport will merely be stains from rapidly rusting fine particles of steel, if allowed to develop further, a loss of zinc coating in the stained areas will appear. Nails, particles of steel, etc. will also stain and ultimately reduce the life expectancy of sheets. Sheets are often subject to wet cement splashes that create an area that is subject to alkali attack. Cement splashes should therefore be cleaned off immediately.

Note: During installation, clean the roof daily by removing all swarf, pop rivets and unused fasteners or an other debris.Wind terraine categories

It is important to consultant an engineer at design stage, to ensure the correct specification of purlin spacing and roof sheet gauge.

Corrosion

The coast line of Africa is a particularly harsh enviroment which carries coastal chlorides. In urban areas, corrosion is accelrated by the presence of sulphur emissions from industry and traffic. The choice of the correct steel substrate is therefore important to avoid high replacement costs and losses in rentals, etc. Please request additional information from Nyumba Group in this regard.

PREVENTING JOBSITE STORAGE CORROSION OF PREPAINTED SHEET

Corrugated Sheets Limited is an industry player that adheres to the higest quaity standards and ensures that the products that reach our clients are of the highest quality. That being said, it is incumbent upon job site professionals, business owners, distributors and contractors to ensure proper care is taken to preserve and protect the integrity and attractive appearance of CSL‘s Nyumba Brand products against damage cnused by moisture, corrosive chemicals or improper handling and storage. For Corrugated Sheets Limited Nyumba Roofing Sheets, the following are some basic storage instructions that would ensure the products retain the highest quality while on the job site.

- Firstly, on a job site, order the roofing sheets on a schedule that ensures that they stay in storage the shortest time.

- Offload the roofing sheets directly to the job site or storage facility to reduce the risk of damage during translocation from one location to another.

- When manually off-loading, ensure the appropriate operatives are on hand, wearing adequate protective clothing as the roofing sheet edges are sharp.

- The sheets should be stored elevated on a raised base in a dried and a secured location not exposed to the elements i.e. wind, rain and covered with a waterproof cover or canvas tarpaulin. Do not use plastic as it causes sweating and condensation to occur.

- Moisture is what causes the most damage to roofing sheets hence the raised and slightly sloped base to ensure any errant moisture that gets on the sheets drains away.

- Sufficient support must be provided to the raised and angled bundles to avoid excessive bowing, which may result in low spots that could hold water.

- Do not store any heavy materials on top of the sheets while in storage.

- If the roofing sheets are of the pre-painted variety, store them with the coloured face facing downwards to ensure minimal scratches and damages while in storage.

- In order to prevent unwanted chemical reactions and corrosion, do not store the sheets with materials made of dissimilar metals (lead, copper, etc.).

- Strong acids (jet fuel exhaust, commercial cleaners/solvents, etc.) can degrade the finish.

- Inspect the storage site regularly to ensure moisture protection. If errant moisture on the sheets is noticed, separate the stacked sheets, wipe them down with a clean dry cloth and allow to completely dry before restacking.

NOTE TO CLIENT: If any moisture is noticed on the roofing sheets by the client on delivery, DO NOT accept the delivery and immediately contact your distributor.

Following these simple instructions would ensure the product retains the highest quality while on a work site or in storage.

JOB SITE STORAGE:

If sheet bundles have to be stored outdoors, a number of precautions must be taken to prevent storage corrosion. The sheet bundles should be stored in a area out of the way of other construction activities to minimize the number of bundle movement s required at the job site. If the bundles are stored on the ground, a plastic ground cover must be put down under the bundle to minimize condensation of water from the ground onto the sheets. The bundles must then be raised off the plastic ground cover to avoid contact with water puddles, and allow for air circulation around the bundle to promote drying of condensed water. The sheets must be stored on an angle to promote drainage of water off the bundle. Sufficient support must be provided to the raised and angled bundles to avoid excessive bowing, which may result in low spots that could hold water. We advice to all our customers to follow this technical information and minimize premature failures of pre-painted sheets.

Corrugated Sheets Limited (CSL) is your one-stop shop for all your construction needs. Under the Nyumba brand, the company has an annual capacity of over 300,000 MT of various steel products in mixed ranges.

Mikindani, Mobasa-Nairobi Rd,

P.O Box 83594 - 80100

TALK TO US:+254 722 204848

+254 727 605899

+254 733 615465

csl@nyumba.com

Corrugated Sheets Limited (CSL) is your one-stop shop for all your construction needs. Under the Nyumba brand, the company has an annual capacity of over 300,000 MT of various steel products in mixed ranges.

New Mombasa - Nairobi Road, Mikindani

P.O. Box 83594 - 80100,

Mombasa, Kenya.